|

Leak Detection System |

| |

|

| |

|

| |

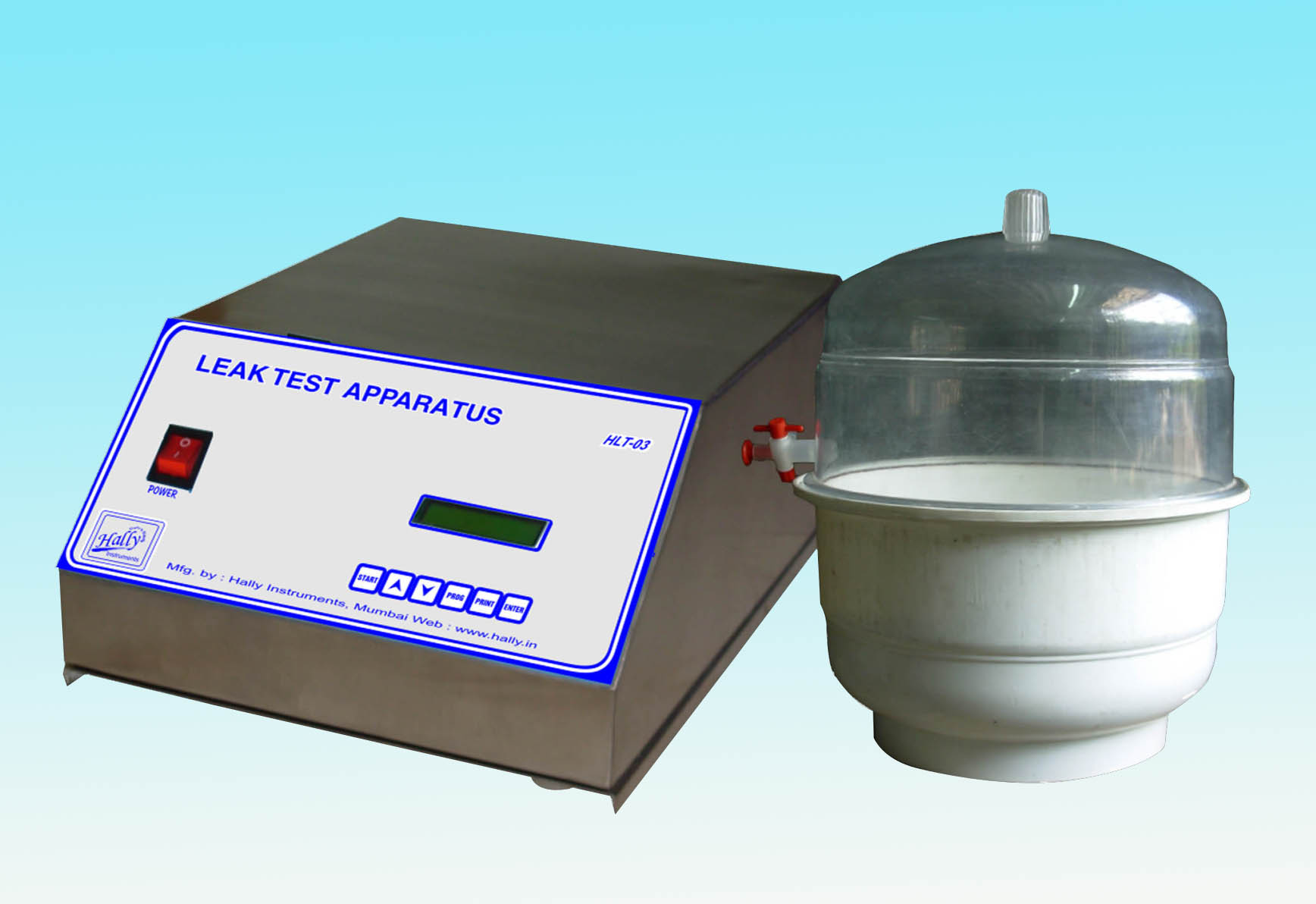

The vacuum leak detection system HLS 03 finds smallest leaks and holes in tablet blister and other flexible, semi-rigid packages.

|

| |

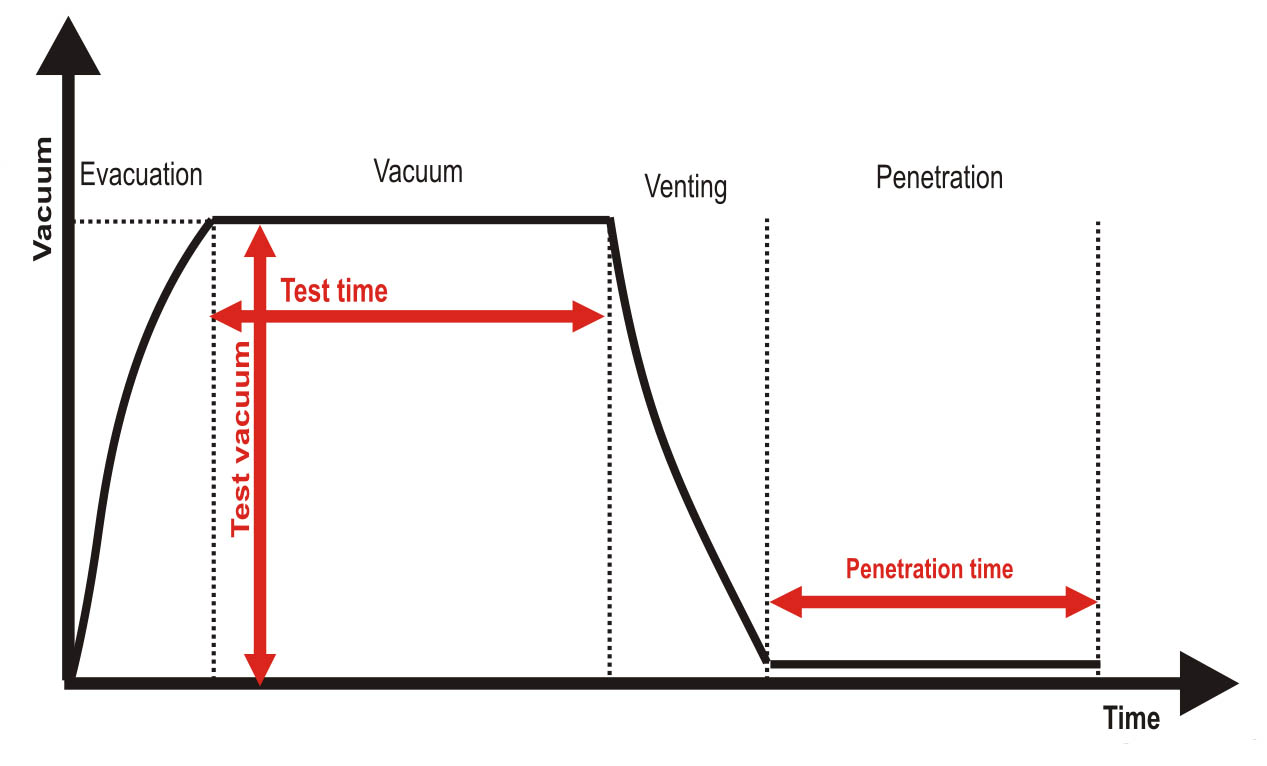

Vacuum, test and penetration time are adjustable and can be stored into a database, this ensures that identical products will always be tested with the same parameters so that tests are repeatable |

| |

SALIENTS FEATURES |

| |

-

16 x 2cm Large size numericl LCD display

-

Fully Micro controlled operation

-

Continues display of process valve along with vacuum level

-

Vacuum and time be programmed

|

| |

THE HOLDMODE |

| |

|

| |

The holdmode is divided into the following |

| |

|

| |

Evacuation of the desicator |

| |

The test time for vacuum exposure will stress the

package to exact periods |

| |

venting the desiccator |

| |

The blister pack remains under atmospheric

pressure. This ensures that the day penetrates

into fine capillaries |

| |

|

| |

|

| |

TECHNICAL DATA : |

| |

| Supply :- vacuum source : Inbuilt double-headed membrane vacuum pump |

| supply voltage : 230 V AC |

| frequency : 50/60 Hz |

| |

| Units :- pressure units : mmHg |

| vacuum : adjustable up to max 600mmHg. |

| accuracy : ± 1% FSC |

| |

Environment Temperature : ± 5....+ 400 C

|

| air RH : 0....90% non condensing |

|

| Optional :- Polycarbonate vacuum desiccator. |

| Built in portable, maintenance free, oil free vacuum pump. |

| Automatic release of vacuum from desiccator after completion of process with audio |

| alarm. |

| Low power consumption. |

|

| Size :- 250 x 370 x 200 mm |

|

| Body :- complete Stainless steel 304 |

|